|

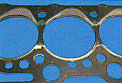

PHOTOGRAPH (1) |

|

PHOTOGRAPH (2) |

|

|

| CENTRE BRIDGE BURN |

| |

| FEATURES: |

|

| Note blackening between bores which progress to burn through

failure as in second photo. |

| CAUSES: |

|

(a) Inherent distortion of head or block denying lack of clamp

between bores.

(b) Distortion due to overheating. |

|