|

|

GASKET - FAULT FINDING

|

|

|

|

| INCORRECT APPLICATION |

|

| |

| FEATURES: |

|

|

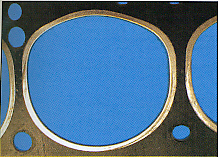

Underside of all fire rings (i.e. block side) exhibit distinct

impressions

where pistons have hit the head gasket. |

| CAUSES: |

|

| Head gasket incorrect for application. |

|

| GENERAL: |

|

Several Vehicle Manufacturers produce small & large series

engines using the same basic engine but with varying size cylinder bores.

It is thus essential that during head gasket replacement that the fitter ensures that the gasket fire rings are

circumferential clear of the bore, normally 1 mm To

3mm on diameter.

Under no circumstances must the gasket fire ring bores overhang the cylinder bores. |

| |

|

|

|

|

|

|

| DIRTY ASSEMBLY |

|

| |

| FEATURES: |

|

|

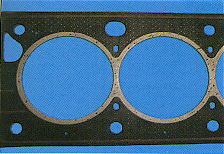

| Foreign particles trapped and crushed into the fire ring

faces and composite facings. |

|

| CAUSES: |

|

|

| Particles dropping from water galleries during placement of head. |

|

| GENERAL:: |

|

| Since the cylinder head is normally dry when being re-installed

it is possible for rust deposits and similar contaminents to detach and fall from the water galleries onto the

head gasket. These particles can create gutter paths for combustion gases which will quickly burn back into adjacent

bore or water galleries etc. |

| REMEDY: |

|

| We suggest thorough flushing of the head, preferably with detergent

and a high pressure washer followed by additional air line cleaning. Only fit the cylinder head when confident

that no further media is falling from the water gallery portings. |

| |

|

|

|

|

|