|

CAMSHAFT FOLLOWER

DESIGNS & |

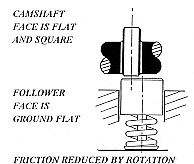

Bucket camshaft followers are found in O.H.C. engines and transmit the camshaft lift directly onto the valve stem end. Both the cam follower and camshaft lobes are ground square and flat. By offsetting the camshaft lobe towards the outside of the follower, a rotating action is created. This type of cam assembly is the most efficient in terms of reduced friction and long term reliability. Bucket followers are normally adjusted by shims or actuated hydraulically and as a rule can be renewed against an existing camshaft with a high success rate.

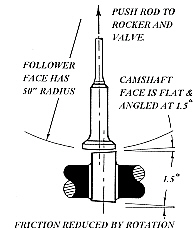

Barrel or stem headed followers normally transmit the camshaft lift via pushrods &/or rocker arms onto the valve stem end. They are found in both OHV & OHC engines. The cam follower faces are ground with a convex radius of some 50", whilst the cam lobe is ground with a very small angle of 1.5 degrees. This combination of angles results in only half of the follower face being in contact with the camshaft lobe & thus a friction reducing rotating action is imposed on the follower. Since barrel follower diameters are small in comparison to bucket followers, then their life expectancy is not as good. Barrel followers can be solid or hydraulic and should only be renewed on old cams with great precaution. If the convex radius of the follower has worn flat or even worse worn concave (dished inwards), then the camshaft must have worn also. By combining new followers on a worn cam, point loading of components results and rapid wear and failure will commence very quickly.

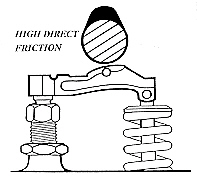

Finger arm cam followers are employed in O.H.C engines. They impose their movement directly from the cam lobe onto the valve stem end about a fixed pivot point being the ball stud. Lubrication is normally fed either through holes in the base circles of each cam lobe or through a separate oil feed pipe. This type of configuration creates a direct sliding friction and accordingly depends more so on ample oil supply then those of rotating followers. Finger arm followers with hydraulic lifter ball studs run in constant contact with the cam lobe so frictional forces are even more demanding. It is thus of vital importance that lubrication is foremost in consideration of life expectancy of a camshaft kit of this design.

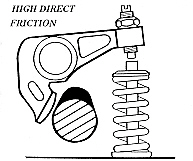

Rocker arm cam followers are again confined to O.H.C engines and transmit the cam lift onto the valve stern end by pivoting on a central rocker shaft. Like finger arm followers the rocker face slides directly on the cam producing a high sliding friction. Lubrication is normally fed through the rocker shaft into a feed in the rocker which jets right onto the cam & follower face. Other types rely on a separate oil feed pipe. Again lubrication is of utmost importance in any camshaft kit replacement.