|

CAMSHAFT KIT FAULT FINDING |

| LUBRICANT PARTICLE CONTAMINATION | ||

|

|

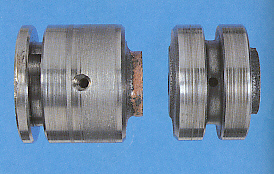

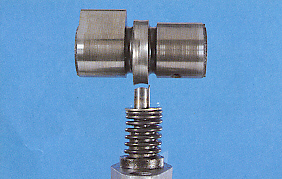

FEATURES | |

| 1) L/H Failed Follower Has Severe Body Scratches. Top Button Has Collapsed. 2) R/H Normal Follower Has Polished Body. Top Button Is Proud. |

||

| CAUSES | ||

| 1) Lubricant Contaminated With Tiny Metal Particles. Inherent

From Previous Failure. 2) Internal Parts Of Follower Become Scored, Seize & Collapse. |

||

| REMEDY | ||

| 1) Engine Requires Thorough Cleaning Which Might Involve Total Strip Down. | ||

| THE ABOVE PHOTOGRAPHS DISPLAY COMMON CAMSHAFT KIT FAILURES ASSOCIATED WITH UNPROFESSIONAL FITTING OR INHERENT ENGINE PROBLEMS. CAMSHAFT KITS RETURNED UNDER WARRANTY DISPLAYING THESE FEATURES WILL BE REJECTED AS NOT BEING OF FAULTY MANUFACTURE. |