|

|

QUICK TIP - FAULT

FINDING FOR NEWLY ASSEMBLED CAM-KITS

IN ALL CASES ASSUMPTION IS MADE THAT BASIC CHECKS ARE CARRIED OUT FIRST.

|

|

|

1) OIL FLOW 2) OIL PRESSURE 3) VALVE CLEARANCES

(Where Applicable)

4) CAMSHAFT / VALVE TIMING 5) DISTRIBUTOR / PUMP TIMING

6) FUEL SUPPLY 7) SPARK & DISTRIBUTION 8) COMPRESSION TEST

|

| VEHICLE MAKE / ENGINE TYPE & CAM KIT PART NO. |

NOISY TAPPETS

|

ENGINE MISSFIRE

|

|

|

A)

Check 1,2,4.5

B) Hydraulic Followers Not Bled Run For 20 Mins At Fast Idle

C) Ensure Rockers & Shafts Are Not Worn

D) See If Valve To Rocker Clearance Exists. If So Push Rod Ends May Have Worn.

E) Airation In Oil Due To Engine Oil Overfill.

F) Contamination Of New Hydraulic Followers. |

A)

C See- 2,4,5,6,7,8 |

|

|

A)

Check 1,2,4,5

B) Hydraulic Columns Not Bled Run For 20 Mins At Fast Idle.

C) Airation In Oil Due To Engine Oil Overfill.

D) Contamination Of New Hydraulic Columns.

E) Thrust Pads Worn. |

A)

Check 2,4,5,6,7,8

B) Original Hydraulic Columns Not Cleaned And Decompressed. |

|

|

A)

Check 1,2,3,4,5

B) Worn Ball Studs &/Or Weak Follower Retaining

Springs. Butterfly Wings Must Point Into Camshaft.

Recrimp Up & Over Springs So They Are Really

Tight To Assemble.

C) Tinder Tensioned Timing Belt. |

A)

Check 3,4,5,6,7,8

B) Cam & Distributor Timing Out Of Syncro. Check That Timing Disc Behind Cam Pulley Has Not Moved

During Assembly. Pointer Should Be Dead Centre Of Pulley Window.

C) Split Inlet Gasket Is Common Fault. |

|

|

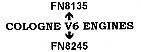

A)

Check 1,2,3,4,5

B) Early Cam Fitted In Late Block. Resultant Low

Oil Pressure & Varying Valve Clearances.

C) Rockers & Shafts Worn.

D) Oil Ways In Head &/Or Rocker Pillars Blocked. |

A)

Check 3,4,5,6,7,8

B) Backlash In Camshaft Gear & Crankshaft Gear. |

|

|

A)

Check 1,2,4,5

B) Recheck Cam & Follower Housings Of Head For Oversize.

C) Hydraulic Followers Not Bled Run For 20 Mins At Fast Idle.

D) Contamination Of New Hydraulic Followers.

E) Airation Of Oil Due To Overfill &/Or Oil Pump Pressure Relief Valve Over Exhausting. ( Oil Will

Appear Creamy).

F) Incorrect Oil Filter Allowing Follower Bleedback (More Apparent At Initial Start Up After Standing)

G) Under Tensioned Timing Belt Promoting Distributor Rattle

H) Rocker Cracked Or Poor Seating On Rocker Pivot. |

A)

Check 2,4,5,6,7,8

B) Rectangular Spacer plate Missing From Underneath Rocker Arm Pivots Causing Followers To Overlift. |

|

|

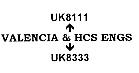

A)

Check 1,3.4,5

B) Valve Clearances Erratic! Incorrect Cam Kit Fitted.

Follower Stems To Small For Later J.L.A & H.C.S Blocks

C) Ensure Rockers & Shaft Are Not Worn.

D) Check That Rocker Shaft & Retaining Bolts

Haven't Snapped! |

A)

Check 2,3,4,5,6,7,8

B) Recheck Valve Sequence Beginning at Engine Front. Valencia & J.L.A. Engines Upto 1988 = Ex, In.

Ex, In. Ex, In. Ex, In. H.C.S. Distributor Less Engines 1988-On = Ex, In. Ex, In. In, Ex. In, Ex. Incorrect Kit

Fitted If Only Firing On Two!. |

|

|

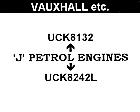

A)

Check 1,2,4,5

B) Hydraulic Columns Not Bled Run For 20 Mins At Varying Rev Ranges.

C) Airation In Oil Due To Engine Oil Overfill. (Oil Will Appear Creamy).

D) Valve Colletts & Caps Pulled, Causing Thrust Pad Not To Sit On Valve Stem End.

E) Under Tensioned Timing Belt Causing Distributor Rattle On Early Key Slot Distributors.

F) Spring Base Cup Assembled Upside Down Causing Spring To Coil Bind. |

A)

Check 1,2,4,5,6,7,8

B) Original Hydraulic Columns Not Cleaned Or Decompressed.

C) Fuel Pump Rod Sticking Due To Disturbance & Body Distortion. Retorque Pump Nuts Until Fuel Pump

Rod Releases Or Renew Fuel Pump.

D) Incorrect Geometry Between Valve End, Rocker & Cam. Running Witness Area On Rocker Should Be

Central About The Rocker Face. If Witness Area Is Biased Towards Valve Spring End Of Rocker, Then Contact Our Technical

Department. |

|

|

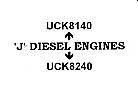

A)

Check 1,2,4.5

B) Check As Above "J" Series Petrol Kits.

C) Incorrect Head Gasket Thickness Causing Piston & Valve Collision.

D) Head Reface Allowing Excessive Valve Protrusion & Resultant Piston & Valve Collision.

E) Early Cam Kit Fitted In Late Engine. Over Lift Of Valves Will Cause Piston & Valve Collision.

F) Cam Timing Has To Be Exact. |

A)

Check 1,2,4,5,6,7,8

B) Original Hydraulic Columns Not Cleaned Or Decompressed.

C) Incorrect Geometry Between Valve End, Rocker

& Cam. Running Witness Area On Rocker

Should Be Central About The Rocker Face. If

Witness Area Is Biased Towards Valve Spring End Of Rocker, Then Contact Our Technical Department.

D) Cam & Fuel Pump Timing Have To Be Exact. |